| Model | LSVI-50 | ||

| Applicable materials | Rubber, plastic etc. | ||

| Clamping force | 50 tons (adjustable within 30MPa) | ||

| Max. operating temperature | 450℃ | ||

| Temperature control accuracy | ±2℃ | ||

| Heating/cooling method | Electric heating/compressed air or water cooling | ||

| Press platen size | 300mm×300mm×60mm | ||

| Press platen spacing | 150mm | ||

| Work layer | Single-layer, two-platen | ||

| Gradient pressurization | 2 sections | ||

| Exhaust | 0-10 times(adjustable) | ||

| Cylinder speed | 11-50mm/s | ||

| Pressure measurement range/accuracy | 0-60MPa,0.5%F.S | ||

| Oil pump motor power | 3.7kW | ||

| Vacuum pump motor power | 1.5kW | ||

| Vacuum degree | <10mbar (Above sea level) | ||

| Control | SIEMENS PLC | ||

| Working voltage | Three-phase 380VAC±10%,Single-phase 220VAC±10%,50Hz | ||

| Rated power | Approx.14kW | ||

| L x W x H | 1720mm×670mm×1610mm | ||

| Weight | Approx.1000kg |

The vulcanizer consists of hydraulic cylinder, hydraulic station, chamber, upper and lower heating plate and PLC control system. The polymer material can be shaped in a specific mold. The pressure, temperature (up to 300°), time, exhaust times and seconds, HMI OS, dynamic real-time display and monitoring of vulcanization process can be set. Squeezing is completed automatically, the vulcanizer with simple structure has the features of wide applicability, high efficiency etc.

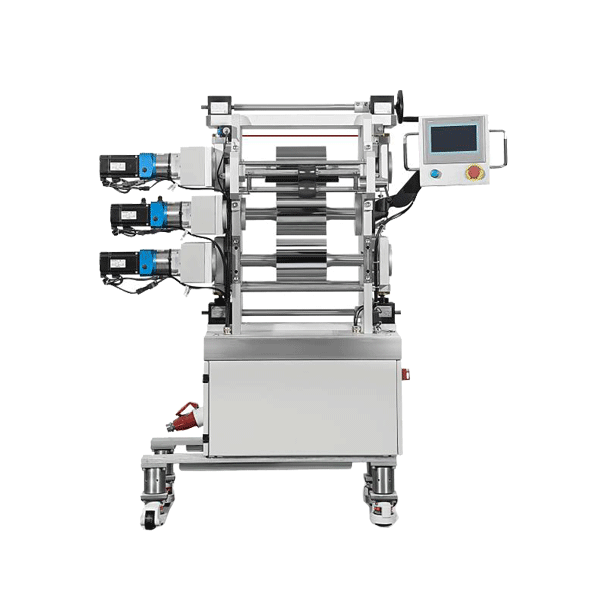

The calender consists of precision calender roll, high-strength aluminum alloy wall panel and frame. The calendering rolls are heated or cooled by the heat-conducting medium running through. Each roller is controlled by an independent servo motor via PLC. The calendar is suitable for experiment or batch production of various polymer films and sheets.

The rollers with hard chrome plating surface are driven by two independent servo motors. The roll surface temperature is controlled within 5 degrees with the interior heating and water/air cooling system. It is suitable for mixing and dispersing natural rubber and other polymer materials.