| Model | FOOI-100 | ||

| Minimum size of stretched sample | 80×80mm | ||

| Max. thickness of stretched sample | 3mm | ||

| Max. stretching ratio | 10 times | ||

| Clip number | 5pcs each side | ||

| Max. stretching speed | 500mm/s | ||

| Stretching force per axis | 2000N | ||

| Clip air pressure | 5MPa | ||

| Speed mode | Constant line speed | ||

| Stretching temperature | 250℃ | ||

| Total power | 25kW | ||

| L x W x H | 4000mm×2300mm×1850mm |

The film blowing machine is the basic equipment for the polymer material molding experiment. Based on the integrated design concept, the FBVI-20/28 desktop film blowing machine of Guangzhou Putong Experimental Analysis Instrument Co., Ltd. creatively integrates the single-screw extruder, film blowing die head and traction, winding auxiliary machine, and film The bubble cooling system and electronic control system are integrated into a movable rack. The equipment does not need on-site adjustment, and it can be used after the user is powered on and ventilated, which is extremely convenient.

Mixing chamber has volume of 55mL, 200mL, 300mL as options, the Torque Rheometer has drive and control measurement functions and equipped with precision torque sensor, precision planetary reducer and servo motor. It is used to analyze the plasticization and rheological properties of polymer materials, helping users to carry out inspection and processing design of raw material.

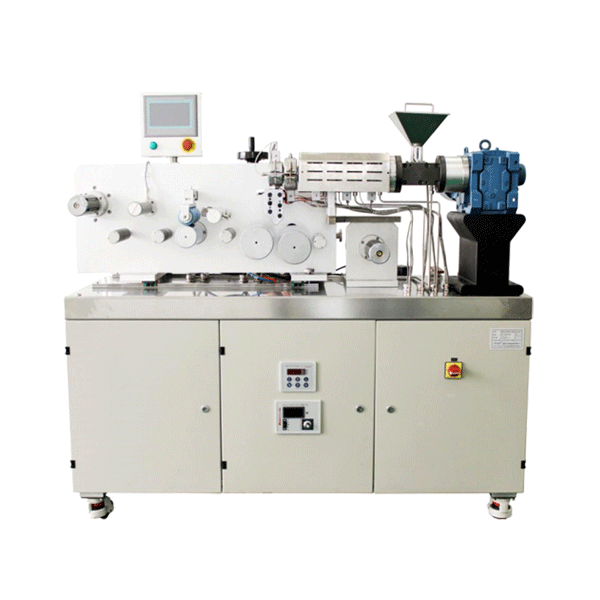

The casting film line is composed of precision screw extruder, die, casting roll, cooling roll, haul-off roll, and winding roll. The screw has diameters from 20 to 30 and a length to diameter ratio of 1:28, and can be equipped with a 100 or 150 mm die. Suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.