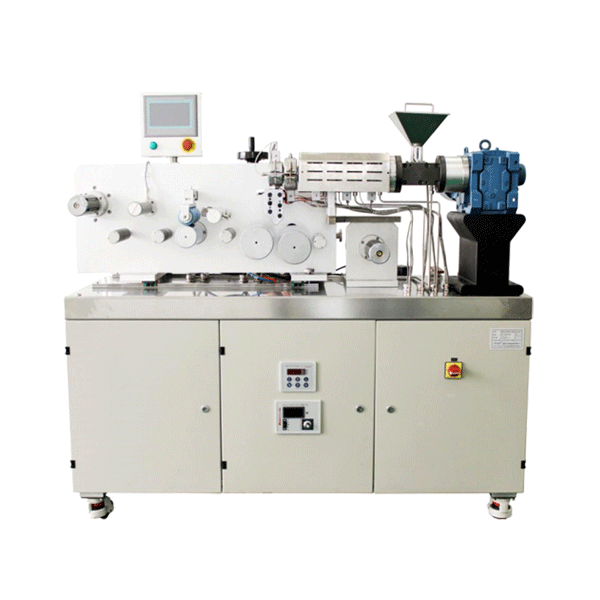

The film blowing machine is the basic equipment for the polymer material molding experiment. Based on the integrated design concept, the FBVI-20/28 desktop film blowing machine of Guangzhou Putong Experimental Analysis Instrument Co., Ltd. creatively integrates the single-screw extruder, film blowing die head and traction, winding auxiliary machine, and film The bubble cooling system and electronic control system are integrated into a movable rack. The equipment does not need on-site adjustment, and it can be used after the user is powered on and ventilated, which is extremely convenient.

Mixing chamber has volume of 55mL, 200mL, 300mL as options, the Torque Rheometer has drive and control measurement functions and equipped with precision torque sensor, precision planetary reducer and servo motor. It is used to analyze the plasticization and rheological properties of polymer materials, helping users to carry out inspection and processing design of raw material.

The capillary rheometer consists of precision screw extrusion system, capillary die or narrow slit die, and weighing unit. There are optional dies with different caliber and aspect ratio, extrusion by screw allows the polymer to pass through the capillary at a constant flow rate, by testing the pressure drop created between the two specific pressure points, under these conditions, the shear stress and shear rate of the polymer melt with Newtonian rheological properties were calculated through the software.

The 3D printer filament extrusion line consists of precision screw extruder, micro water channel, laser caliper, and precision coiler for extra neat winding of filament. Equipped with dies with different size for different diameters of filament. Suitable to be used in the laboratory due to the features of mini size and low noise during operation, and it is used for small batch production as well.

The casting film line is composed of precision screw extruder, die, casting roll, cooling roll, haul-off roll, and winding roll. The screw has diameters from 20 to 30 and a length to diameter ratio of 1:28, and can be equipped with a 100 or 150 mm die. Suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.

The mini casting film line consists of precision screw extruder, die, casting roll, cooling roll, haul-off roll, tension roll, winding roll, and waste edge winding roll. It can be equipped with 150-200mm die, suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.

The filtration pressure value tester consists of precision screw extrusion system and special melt pump. The melt pressure sensor is installed in front of the pump and a pressure-screw-speed control loop is formed. Screen changer can be disassembled and assembled easily and quickly for easy replacement of the screen, the perforated plate support multi-layer screen. The test curves and reports of FPV filtration pressure value can be generated by testing and recording the pressure changes during polymer extrusion with melt pressure sensor through dedicated software.

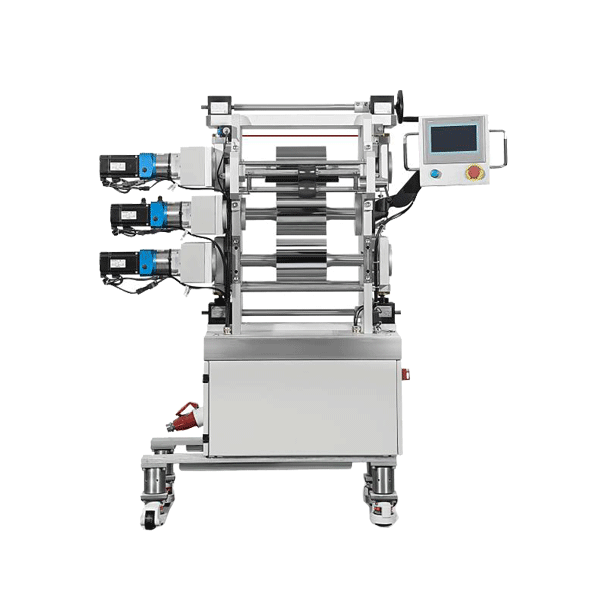

The calender consists of precision calender roll, high-strength aluminum alloy wall panel and frame. The calendering rolls are heated or cooled by the heat-conducting medium running through. Each roller is controlled by an independent servo motor via PLC. The calendar is suitable for experiment or batch production of various polymer films and sheets.

Equipped with vacuum pump for vacuum chamber. The vulcanizer consists of hydraulic cylinder, hydraulic station, vacuum chamber, upper and lower heating plate and PLC control system. The polymer material can be shaped in a specific mold. The pressure, temperature (up to 450°), time, exhaust times and seconds, HMI OS, dynamic real-time display and monitoring of vulcanization process can be set. Squeezing is completed automatically, the vulcanizer with simple structure has the features of wide applicability, high efficiency etc.

The vulcanizer consists of hydraulic cylinder, hydraulic station, chamber, upper and lower heating plate and PLC control system. The polymer material can be shaped in a specific mold. The pressure, temperature (up to 300°), time, exhaust times and seconds, HMI OS, dynamic real-time display and monitoring of vulcanization process can be set. Squeezing is completed automatically, the vulcanizer with simple structure has the features of wide applicability, high efficiency etc.

Film biaxial tensile tester is a common equipment for testing the biaxial tensile properties of polymer sheet films. The film biaxial stretching instrument developed by Guangzhou Putong can make the thickness below 0.2-2mm, and the minimum 70×70mm can be used as a thick film sample of biaxially stretched film material. According to the required stretching ratio, it can be formed at a suitable temperature and time. The film tensile test is used for physical and chemical testing and analysis in the laboratory. According to the properties of the sample film, a wide variety of additives and formulas can be re-determined and applied to the production line, which can greatly reduce the trial production cost.

The rollers with hard chrome plating surface are driven by two independent servo motors. The roll surface temperature is controlled within 5 degrees with the interior heating and water/air cooling system. It is suitable for mixing and dispersing natural rubber and other polymer materials.

Main Test & Control Module is a control console with the function of driving and controlling measurement units. This modular structure has good expandability and adaptability, and can be equipped with various functional modules. Controlled auxiliary machines such as torque and extrusion units are intelligent, application-specific measurement units that transmit measurement data to the host.

The torque module is connected with Main Test & Control Module to constitute a torque rheometer, which is used to analyze the plasticization and rheological properties of polymer materials, helping users to carry out inspection and processing design of raw materials.

This capillary extrusion module is connected with Main Test & Control Module, together with the capillary die and the weighing unit to constitute a capillary rheometer. By testing the pressure drop created between the two specific pressure points, under these conditions, the shear stress and shear rate of the polymer melt with Newtonian rheological properties were calculated through the software.