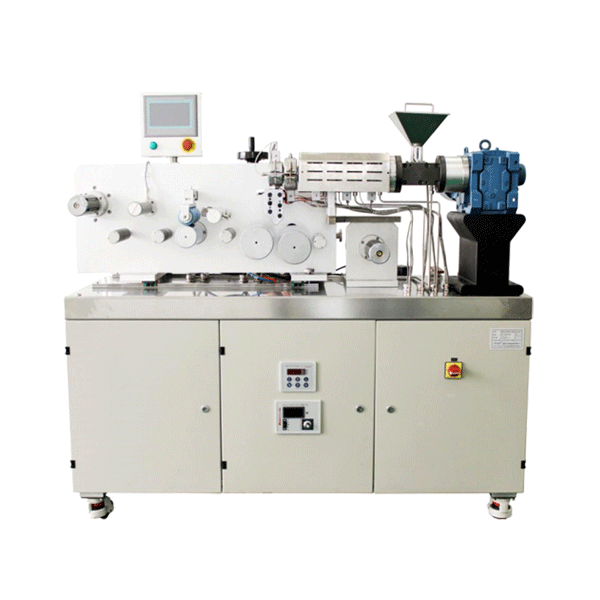

| Model | FDSI-25/28 | ||

| Applicable materials | PE、PP etc. | ||

| Screw diameter | 25mm | ||

| L/D | 28 | ||

| Screw speed | 0-120rpm | ||

| Die width | 200mm | ||

| Product width | 0-120mm | ||

| Product thickness | 0.02-0.1mm | ||

| Roller width | 220mm | ||

| Line speed | 0-10m/min | ||

| Pressure measurement range/accuracy | 0-50MPa,0.5%F.S | ||

| Heating/cooling method | Electric heating/Fan cooling | ||

| Operating temperature | Room temperature-350°C | ||

| Temperature control accuracy | ±1℃ | ||

| Max. output | 5kg/h | ||

| Main motor power | 5.5kW | ||

| Control | SIEMENS PLC | ||

| Working voltage | Three-phase 380VAC±10%,Single-phase 220VAC±10%,50Hz | ||

| Rated power | Approx 20kW | ||

| L x W x H | 2800mm×690mm×1500mm | ||

| Weight | Approx 800kg |

The film blowing machine is the basic equipment for the polymer material molding experiment. Based on the integrated design concept, the FBVI-20/28 desktop film blowing machine of Guangzhou Putong Experimental Analysis Instrument Co., Ltd. creatively integrates the single-screw extruder, film blowing die head and traction, winding auxiliary machine, and film The bubble cooling system and electronic control system are integrated into a movable rack. The equipment does not need on-site adjustment, and it can be used after the user is powered on and ventilated, which is extremely convenient.

The casting film line is composed of precision screw extruder, die, casting roll, cooling roll, haul-off roll, and winding roll. The screw has diameters from 20 to 30 and a length to diameter ratio of 1:28, and can be equipped with a 100 or 150 mm die. Suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.

The mini casting film line consists of precision screw extruder, die, casting roll, cooling roll, haul-off roll, tension roll, winding roll, and waste edge winding roll. It can be equipped with 150-200mm die, suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.

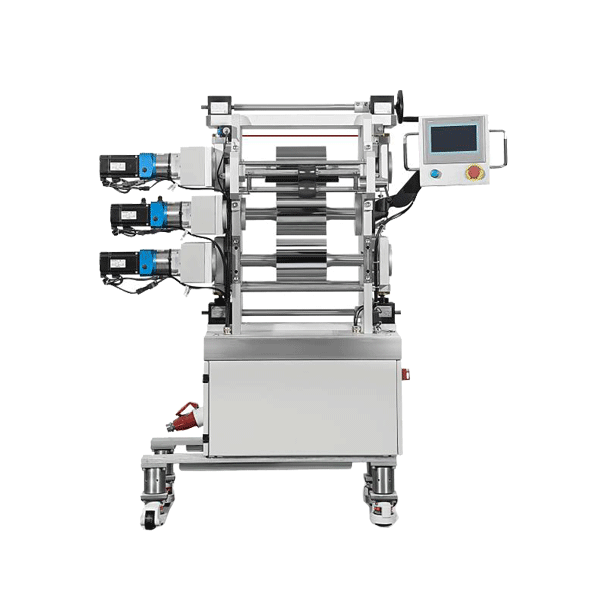

The calender consists of precision calender roll, high-strength aluminum alloy wall panel and frame. The calendering rolls are heated or cooled by the heat-conducting medium running through. Each roller is controlled by an independent servo motor via PLC. The calendar is suitable for experiment or batch production of various polymer films and sheets.

The rollers with hard chrome plating surface are driven by two independent servo motors. The roll surface temperature is controlled within 5 degrees with the interior heating and water/air cooling system. It is suitable for mixing and dispersing natural rubber and other polymer materials.