Company Profile

GUANGZHOU POTOP CO., LTD.

Founded in 2009

Mechanical Design

Software / Programming

Electronic & Electrical Design

Polymer Shaping and Processing Solutions

Learn MoreDesign, customize, fabricate and sell polymer Lab & Pilot machines.

We constantly explore our industry and tap into demands from the market, amass extensive experience rooted in our field. Based on our strong R&D strength and technical advantages, we are committed to designing, customizing and fabricating the high-end polymer laboratory and pilot production machines and providing the best and most flexible services.

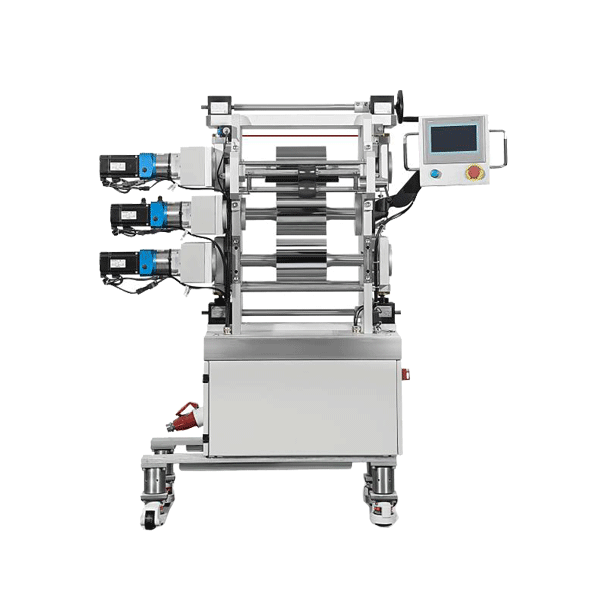

Film biaxial tensile tester is a common equipment for testing the biaxial tensile properties of polymer sheet films. The film biaxial stretching instrument developed by Guangzhou Putong can make the thickness below 0.2-2mm, and the minimum 70×70mm can be used as a thick film sample of biaxially stretched film material. According to the required stretching ratio, it can be formed at a suitable temperature and time. The film tensile test is used for physical and chemical testing and analysis in the laboratory. According to the properties of the sample film, a wide variety of additives and formulas can be re-determined and applied to the production line, which can greatly reduce the trial production cost.

Learn More

The calender consists of precision calender roll, high-strength aluminum alloy wall panel and frame. The calendering rolls are heated or cooled by the heat-conducting medium running through. Each roller is controlled by an independent servo motor via PLC. The calendar is suitable for experiment or batch production of various polymer films and sheets.

Learn More

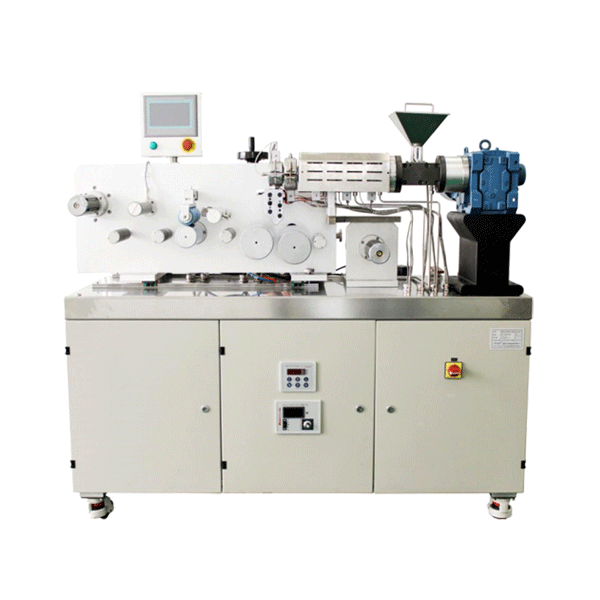

The filtration pressure value tester consists of precision screw extrusion system and special melt pump. The melt pressure sensor is installed in front of the pump and a pressure-screw-speed control loop is formed. Screen changer can be disassembled and assembled easily and quickly for easy replacement of the screen, the perforated plate support multi-layer screen. The test curves and reports of FPV filtration pressure value can be generated by testing and recording the pressure changes during polymer extrusion with melt pressure sensor through dedicated software.

Learn More

The mini casting film line consists of precision screw extruder, die, casting roll, cooling roll, haul-off roll, tension roll, winding roll, and waste edge winding roll. It can be equipped with 150-200mm die, suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.

Learn More

The casting film line is composed of precision screw extruder, die, casting roll, cooling roll, haul-off roll, and winding roll. The screw has diameters from 20 to 30 and a length to diameter ratio of 1:28, and can be equipped with a 100 or 150 mm die. Suitable for making sample and small batch production of polymer extrudate with different thickness by extrusion and casting.

Learn More

The 3D printer filament extrusion line consists of precision screw extruder, micro water channel, laser caliper, and precision coiler for extra neat winding of filament. Equipped with dies with different size for different diameters of filament. Suitable to be used in the laboratory due to the features of mini size and low noise during operation, and it is used for small batch production as well.

Learn More

The capillary rheometer consists of precision screw extrusion system, capillary die or narrow slit die, and weighing unit. There are optional dies with different caliber and aspect ratio, extrusion by screw allows the polymer to pass through the capillary at a constant flow rate, by testing the pressure drop created between the two specific pressure points, under these conditions, the shear stress and shear rate of the polymer melt with Newtonian rheological properties were calculated through the software.

Learn More

Mixing chamber has volume of 55mL, 200mL, 300mL as options, the Torque Rheometer has drive and control measurement functions and equipped with precision torque sensor, precision planetary reducer and servo motor. It is used to analyze the plasticization and rheological properties of polymer materials, helping users to carry out inspection and processing design of raw material.

Learn More

The rollers with hard chrome plating surface are driven by two independent servo motors. The roll surface temperature is controlled within 5 degrees with the interior heating and water/air cooling system. It is suitable for mixing and dispersing natural rubber and other polymer materials.

Learn MorePOTOP has deep knowledge in mechanical engineering, polymer shaping and processing. Combined with automation, electrical and electronic technologies, software development and programming, POTOP designs and fabricates high-end polymer lab & pilot machines for high-performance standard, and even with the ability to provide customers with non-standard polymer lab&pilot machines for specific needs.

Learn More

Case show of POTOP film biaxial stretching instrument

READ MORE

Recently, the Guangdong Plastics Industry Association published a number of group standards, and the general manager of Guangzhou POTOP Co., Ltd. and Zhang Chengyao

READ MORE

In order to carry forward the traditional virtue of respecting the elderly and helping the elderly of the Chinese nation, on October 24,2020, representatives of Guangzhou POTOP Co., Ltd. came to Shuangliang Village

READ MORE